I make all of my own 'Gibert' type sanding discs, takes about 20 mins to make one and I have a selection with different grits on always handy.

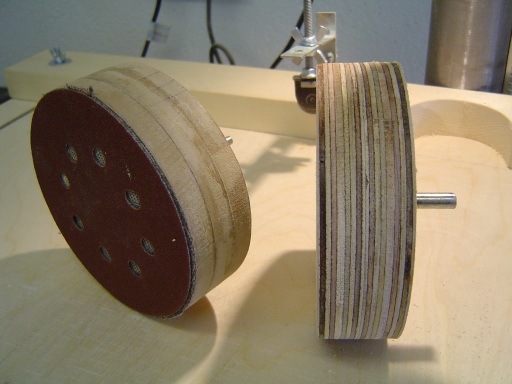

I use off cuts of MDF or Plywood, which are cut to a 5" circle using the circle cutting attachment on my small bandsaw. These are then drilled out using the spike mark from the circle cutter to centre, a flat brad point bit is used to open up a cavity in one face of each to take the bolt. I use 8mm bolts with the head cut off and put a nut and washer both sides of the wood and tighten right down with a bit of locktite on the threads. The two circles of wood are then glued together with PVA.

When set check the level of your table with a bent coat hanger and put some sandpaper on the table face up, I usually use it attached to a board, run the press and slowly lower the sanding disc onto the sandpaper to level the lower face to ensure that it runs level to the table.

Attach velco hook cloth to the underside and your done, 5" ROS dics can then be used.

Long winded explanation, quicker to do than explain. A couple of pictures perhaps.

I have one with a piece of leather stuck to the top which is great for final polishing of chisels etc.

ColinColin S38794.3883333333

|

If you`re not set up with a dust collection system, at least use a respirator! About two months of choking up a lung each morning taught me that lesson. (I thought it was the cheap cigarettes for awhile).

If you`re not set up with a dust collection system, at least use a respirator! About two months of choking up a lung each morning taught me that lesson. (I thought it was the cheap cigarettes for awhile).